Preventing Failures And Prolonging The Life Of Electrical Systems

- Extracted

from Maintenance Technology Magazine by Prof. Matt Mantese.

Most electricians would agree that the essential nervous system of every

facility is the electrical system. The electrical system consists of the main

switch gear, branch circuit panels, transformers, motor control centers and any

other critical electrical equipment.

Proper maintenance of its electrical system is essential for the survival of

any facility, as well as for preventing unexpected electrical interruptions.

This article focuses on a comprehensive program that has been developed

within Aschinger Electric, a St. Louis-based service provider, to help prevent

electrical failures and prolong the life of electrical systems. Performed

annually on all electrical equipment, it includes: infrared scanning, cleaning

and torquing and, finally, an infrared re-scan.

"Infrared" scanning to identify problems

The infrared camera is an excellent tool for identifying potential electrical

problems. All electrical equipment should be scanned as the first step of the

maintenance program. The infrared camera is key to spotting connections that

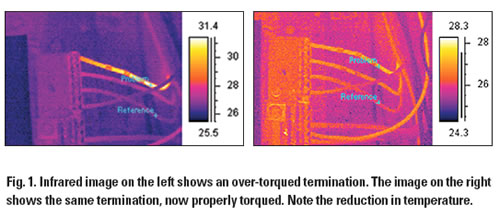

have been improperly torqued or are being overloaded. Fig. 1 illustrates an

overtorqued electrical termination. The problematic point has a temperature of

32 C (90 F). The image at the right shows the same termination after being

properly torqued; the temperature was reduced to 26 C (78 F).

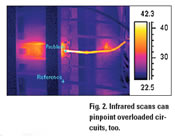

The infrared camera also can identify overloaded circuits. Fig. 2 is an image

of a wire drawing 22.4A. The circuit is rated for 20A. The wire was originally

yellow, but due to the extreme exposure to temperature, it turned brown and

brittle. The wire was able to be replaced and the circuit’s load was

redistributed during a scheduled shutdown rather than during an unexpected

failure of the wire.

All bus links, wire terminations and coils of transformers need to be scanned

while under load.Due to the hazards of scanning energized equipment, it is a

good practice to perform scans with pairs of qualified electricians that are

suited up in personal protective equipment (i.e. - blast suits).

All deficiencies-overtorquing, undertorquing and overloading-should be

documented At this time, an action plan should be developed for correcting the

deficiencies during the un-energized torquing and cleaning step of the

equipment.

Cleaning and torquing

After identifying all deficiencies using the infrared camera, the equipment

needs to be cleaned, followed by torquing of all terminations to manufacturer’s

specifications.

The initial step in cleaning any electrical equipment is to properly

de-energize the equipment, then to lock out and tag the disconnecting means. A

proper lockout/tagout program is a must in every facility.

To clean a piece of equipment, an industrial- strength hepa vacuum is needed.

Vacuum all pieces of the electrical equipment. Next, using a soft paint brush

with fine bristles, brush out all dust and dirt, working from top to bottom and

left to right, while

After all electrical equipment has been thoroughly cleaned, all terminations

should be loosened, cleaned and lubricated with a manufacturer’s specified

lubricant for the materials being connected ( i.e., no-ox for copper to

aluminum, Fisk paste for bus links).

|

The final

step before re-energizing is to torque all connections to manufacture’s

specifications. If possible, the manufacturer should be consulted for torque

settings of all equipment bolts and links. If torque values are not available,

Table I is a very good reference. At this time, special care should be taken to

correctly torque the deficiencies found during the initial infrared scanning.

Dry-type transformers should be cleaned in the same fashion with one

addition. After the outer coils of the transformer have been removed of dirt

using a paint brush, the inner windings of the coil need to be cleaned using

compressed gas. Nitrogen is used because it will not bind with the atmospheric

air and thus will not form water within the windings. Proper pressure of the

nitrogen to blow out the windings is 25 lbs/in2 or less.

When all dust and debris have been removed, all metal surfaces (i.e., bus

links) should be wiped down using absolute alcohol and a lint-fee rag. Alcohol

cleans well and does not leave a residue when dried. It is advisable to use the

alcohol on cool equipment and to let it dry before re-energizing. (IMPORTANT:

Alcohol is to be used only on metal parts. Do not use alcohol on insulation or

transformer coils.)

Once all terminations are torqued, all equipment should be inspected for

loose tools and properly closed. The electrical system can now be re-energized.

(IMPORTANT: Follow all safety precautions and make sure all workers are

aware of re-energizing of equipment.)

|

|